The Tuscarora Mountain Tunnels in Pennsylvania have a fascinating history. The older of the two tunnels, built between 1938 and 1940, was designed to carry a railroad that never came into service. Industrialists of the day, William Henry Vanderbilt and Andrew Carnegie, were backers of the scheme which was halted when they struck a deal with rival railroad owners.

SHOTCRETE VS FIRE AND WATER REPLACEMENT OF FLUME 4/5/6 AND 30

On August 14, 2021, the Caldor Fire started in Northern California near Pollock Pines, CA. The fire ended up consuming almost 222,000 acres (90,000 hectares) and seriously threatened South Lake Tahoe. Besides the over 1000 structures that were lost, the fire also burned along a major portion of the El Dorado Irrigation District’s Canal (EID) which provides drinking and irrigation water to numerous communities throughout the area

SHOTCRETE AT MT PLEASANT STATION

Multi-million dollar underground stations are currently under construction on Metro and LRT lines in Toronto, Ontario, Canada. Traditionally, the thick, heavily reinforced structural concrete station walls have been constructed using the conventional form-and-pour concrete construction method. This construction method, while widely used, is not without its challenges.

Many of the underground station sites are in congested urban areas with limited spaces for laydown of concrete formwork, and crane access time for handling and installation of formwork is often on a critical path for completion of station construction.

HIGHLINE GARIBALDI SPRINGS ROCKSCAPE RETAINING WALL

This retaining wall was contracted for a new townhouse development project in Squamish, BC, Canada. Vancouver Shotcrete & Shoring Inc. has serviced many municipalities and private companies over the past 30 years in the fields of shotcrete shoring, pools, and custom rockscapes.

The shotcrete retaining wall was designed to be anchored by Titan 40 self-drilling anchors with a test load capacity of 52,000 lbs (24,000 kg) each, spaced every 6 ft (2 m) on center. The temporary 4 in. (100 mm) shotcrete was reinforced with 4 x 4 x 1 in. (100 x 100 x 25 mm) welded wire mesh, with a 0.8 in. (20 mm) continuous whaler lining to span the load between each anchor. The engineer specified a 5800 psi (40 MPa) shotcrete mix for this purpose.

Outstanding Infrastructure Project

I have a project with a segmental retaining wall. The project is located in Maryland. The CMUs of the retaining wall have significantly deteriorated in several areas. The geo-grid fabric appears to be in good condition in the areas where it could be observed. I suspect the deterioration is caused by saltwater runoff during snow events combined with the freeze/thaw cycles. There are some localized areas where the masonry units have completely disintegrated. The largest area being approximately 4 ft2 (0.37 m2). Is it feasible to remove the deteriorated masonry material, down to a sound surface, and shotcrete the face to restore (or exceed) the structural integrity of masonry units? If so, will this restore the structural integrity of the segmental retaining wall?

Shotcrete is routinely used for the repair of deteriorated concrete masonry and brick. Shotcrete should easily have a minimum compressive strength of 4000 psi (28 MPa) when properly shot and cured. According to the National Concrete Masonry Association, current CMU units have a minimum 2000 psi (14 MPa) compressive strength. Older CMU had a lower 1500 psi (10 MPa) minimum. Thus, the shotcrete placement will be significantly stronger and less permeable than the in-place CMU. This should give the wall better resistance to saltwater and freeze-thaw exposures thus extending useful life.

Depending on the depth of the new shotcrete placement, you may consider mechanically tying the shotcreted layer back to the sound CMU with epoxy or mechanically embedded anchors or j-bolts. Thicker sections may also benefit from the use of a steel wire mesh or fibers.

When shooting onto existing CMU sections, the surface must be properly prepared and then shotcreted with proper shotcrete materials, equipment, and placement techniques. Shotcrete placed onto an existing CMU surface will provide an excellent bond IF the following conditions are met:

- Make sure the surface is roughened and clean.

- The amplitude of roughness should be +/- 1/8th in. (3 mm) or more.

- A high-pressure water blaster (5000 psi [34 MPa] or more) or abrasive blasting can help to roughen and clean the surface.

- Bring the CMU surface to a saturated surface dry (SSD) condition. This means the surface feels damp, but water is not picked up on a hand.

- Make sure the shotcrete placement is properly executed with high-velocity placement and quality materials.

- The shotcrete should have a minimum 28-day compressive strength of 4000 psi (28 MPa).

- Be sure the shotcrete contractor is using an air compressor able to produce at least 185 CFM (5.2m3/min) for wet-mix and 375 CFM (10.6 m3/min) for dry-mix (gunite) of air flow at 100 to 120 psi (0.7 to 0.8 MPa).

- Use of an ACI-certified shotcrete nozzleman is recommended.

- No bonding agent should be used. It will interfere with the natural bonding characteristics of shotcrete placement.

Finally, without details on the loading conditions, and structural details of the original construction, we cannot comment on the structural integrity of the repaired wall. You should contact a professional engineer experienced in concrete repair to evaluate the structural integrity of the wall when repaired.

Mount Pleasant Station, Part 1: Preconstruction Qualification for Shotcreting of Mass Concrete

Multi-million-dollar underground stations are currently under construction on Metro and LRT lines in Toronto, Ontario, Canada. Traditionally, the thick, heavily reinforced structural concrete station walls have been constructed using the conventional form-and-pour concrete construction method. This construction method, while widely used, is not without its challenges.

#1 – Compressive (Strength) Values of Pool Shotcrete

Download#2 – Definitions of Key Shotcrete Terminology

Download#3 – Sustainability of Shotcrete in the Pool Industry

Download#4 – Watertight Shotcrete for Swimming Pools

Download#5 – Monolithic Shotcrete for Swimming Pools (No Cold Joints)

Download#6 – Forming and Substrates in Pool Shotcrete

Download#7 – Curing of Shotcrete for Swimming Pools

Download#1 – Spraying Shotcrete Overhead in Underground Applications

Download#2 – Spraying Shotcrete on Synthetic Sheet Waterproofing Membranes

Download#3 – Encapsulation of Reinforcement in Tunnel Shotcrete Final Linings

DownloadASA Outstanding Shotcrete Awards Program

The ASA Outstanding Shotcrete Project Awards Program exists to recognize excellence and innovation on projects in which the application of shotcrete has played a significant role.

ASA’s Annual Outstanding Shotcrete Project Awards Program provides an exciting real-world demonstration of the exceptional advantages of placing concrete via the shotcrete process. Many sustainability advantages are also inherent in the shotcrete process and play a significant role in winning projects as well as the project owner’s ultimate decision to use shotcrete as the method of concrete placement. Projects must be completed between January 1, 2022, through September 1, 2024, and can be submitted in the following areas: Architecture │ New Construction, Infrastructure, International Projects, Pool & Recreational, Rehabilitation & Repair, and Underground.

To assist in your submission, we have provided submission resources to inform you of the submission guidelines, a list of questions, and a copy of the owner release form. Please email any questions to [email protected].

Award Archive

2024 – Twentieth Annual Outstanding Shotcrete Project Awardees

Outstanding Architecture | New Construction Project

Math, Science & Shotcrete | Holly Springs, NC

Project Name:

Math, Science & Shotcrete

Location:

Holly Springs, NC

Shotcrete Contractor:

Revolution Gunite

Architect/Engineer:

Dewberry Engineering

Material Supplier/Manufacturer:

Revolution Gunite

General Contractor:

Progressive Contracting

Project Owner:

Wake County Public Schools

Outstanding Infrastructure Project

Ice Harbor Dam Draft Tube Modification | Burbank, WA

Project Name:

Ice Harbor Dam Draft Tube Modification

Location:

Burbank, WA

Shotcrete Contractor:

PCiRoads, LLC

Architect/Engineer:

U.S. Army Corps of Engineers, Walla Walla District

Material Supplier/Manufacturer:

Master Builders Solutions

Equipment Manufacturer:

Gary Carlson Equipment / Putzmeister

General Contractor:

Voith Hydro

Project Owner:

U.S. Army Corps of Engineers, Walla Walla District

Outstanding International Project

Modernization Of the Water Treatment Plant In Poznan | Poznan, Poland

Project Name:

Modernization Of the Water Treatment Plant In Poznan

Location:

Poznan, Poland

Shotcrete Contractor:

SPB TORKRET Ltd

Architect/Engineer:

Sweco Poland

Material Supplier/Manufacturer:

SPB TORKRET Ltd

Equipment Manufacturer:

Sika – Aliva, Atlas Copco

General Contractor:

TERLAN/HYDRO-MARKO

Project Owner:

Aquanet S.A.

Outstanding Pool & Recreational Project

Boundless Waters | Hudson River, NY

Project Name:

Boundless Waters

Location:

Hudson River, NY

Shotcrete Contractor:

Drakeley Pool Company

Architect/Engineer:

Hollander Landscape Architects

Material Supplier/Manufacturer:

Brewster Transit

Equipment Manufacturer:

Schwing Concrete Pumps

General Contractor:

Yankee Custom Builders

Project Owner:

Yankee Custom Builders

Outstanding Rehabilitation & Repair Project

Hemlock Reservoir Dam Improvements | Fairfield, CT

Project Name:

Hemlock Reservoir Dam Improvements

Location:

Fairfield, CT

Shotcrete Contractor:

Patriot Shotcrete, LLC

Architect/Engineer:

Tighe & Bond, Inc.

Material Supplier/Manufacturer:

Sika Corporation

Equipment Manufacturer:

Putzmeister America

General Contractor:

Blakeslee Arpaia Chapman Inc.

Project Owner:

Aquarion Water Company of Connecticut

Outstanding Underground Project

Anderson Dam Tunnel | Morgan Hill, CA

Project Name:

Anderson Dam Tunnel

Location:

Morgan Hill, CA

Shotcrete Contractor:

Drill Tech Drilling & Shoring, Inc.

Architect/Engineer:

AECOM

Material Supplier/Manufacturer:

The Quikrete Companies / Bekaert Corporation (Fibers)

Equipment Manufacturer:

Schwing Concrete Pumping

General Contractor:

Flatiron West Inc.

Project Owner:

Santa Clara Valley WateHr District Tunnel Ground

Honorable Mention Project

Kicking Horse Canyon Mountain Stabilization | Golden, BC

Project Name:

Kicking Horse Canyon Mountain Stabilization

Location:

Golden, BC

Shotcrete Contractor:

LRutt Contracting Ltd* / Ocean Rock Art Ltd

Architect/Engineer:

Aecon/Emil Anderson

Material Supplier/Manufacturer:

Golden Concrete Ltd

Equipment Manufacturer:

REED

General Contractor:

Kicking Horse Canyon Constructors

Project Owner:

Government of Canada

Honorable Mention Project

Goose Pond Dam Improvements | Canaan, NH

Project Name:

Goose Pond Dam Improvements

Location:

Canaan, NH

Shotcrete Contractor:

Patriot Shotcrete, LLC

Architect/Engineer:

Gannett Fleming, Inc

Material Supplier/Manufacturer:

Gannett Fleming, Inc

Equipment Manufacturer:

Western Shotcrete Equipment, Inc.

General Contractor:

Michels Construction, Inc.

Project Owner:

New Hampshire Department of Environmental Services

Honorable Mention Project

Édouard-Montpetit Station – Réseau Express Métropolitain | Montreal, Canada

Project Name:

Édouard-Montpetit Station – Réseau Express Métropolitain

Location:

Montreal, Canada

Shotcrete Contractor:

NouvLR

Architect/Engineer:

AECOM / AtkinsRealis

Material Supplier/Manufacturer:

Bekaert / Lafarge Canada

Equipment Manufacturer:

Various equipment manufacturers including Shaft & Cavern

General Contractor:

NouvLR (SNC-Lavalin, Dragados, Aecon, EBC, Pomerleau)

Project Owner:

CDPQ Infra

Honorable Mention Project

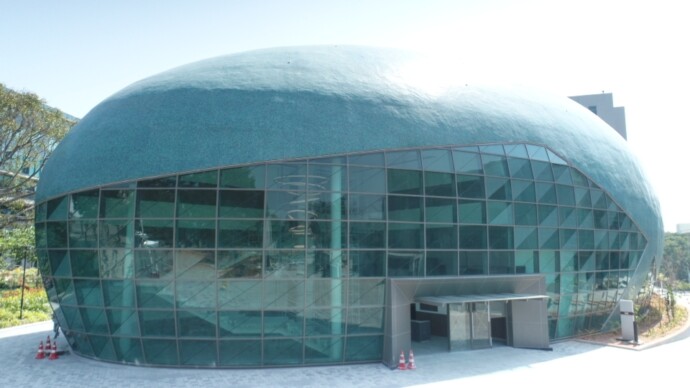

Shotcrete & Waterproofing – Brigade Tech Gardens | Bengaluru, India

Project Name:

Shotcrete & Waterproofing – Brigade Tech Gardens

Location:

Bengaluru, India

Shotcrete Contractor:

Kasturi Projects Private Ltd

Architect/Engineer:

Brigade Properties Pvt Ltd

Material Supplier/Manufacturer:

Prism Johnson Ltd

Equipment Manufacturer:

Epiroc India

Project Owner:

Brigade Properties Pvt Ltd